System¶

Prepared by:

Covered topics:

1. Creating a simple System

2. Retrieving useful information

Video demo:

To run tutorials in your browser, go to this Binder page.

You can also watch a video demo on YouTube (subscriptions & likes appreciated!).

[1]:

import qsdsan as qs

print(f'This tutorial was made with qsdsan v{qs.__version__}.')

This tutorial was made with qsdsan v1.2.0.

Note: although for most of the tutorials the version of qsdsan doesn’t matter, for this tutorial you do want to use v0.3.7 or higher, which addressed some of the bugs in previous versions of qsdsan and biosteam.

1. Creating a simple System¶

System objects are used to organize one or more unit operations in a certain order and facilitate mass and energy convergence, techno-economic analysis (TEA), and life cycle assessment (LCA).

[2]:

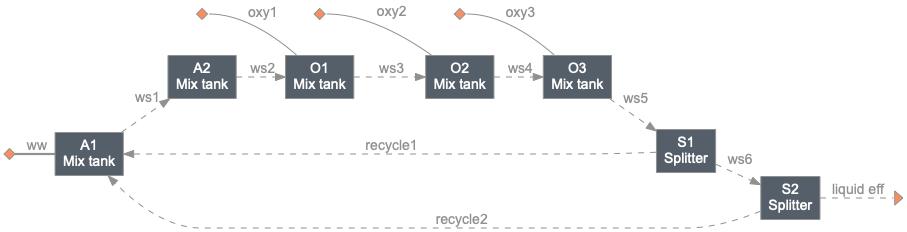

# Assume we want to look at the system in used in benchmark simulation model No.1,

# which looks like this

from IPython.display import Image

Image(url= "https://www.researchgate.net/profile/Ramon-Vilanova/publication/301305911/figure/fig1/AS:352977123594240@1461167712833/Benchmark-Simulation-Model-No-1-BSM1-plant-layout.png")

[2]:

At this stage we won’t include any of the process models (will be covered later in other tutorials), we will just use some surogate units to represent it

So we’ll want to firstly have two anoxic reactors (mix tanks without O2), followed by three aerated reactors (mix tanks with O2), and a clarifier (splitter)

Note that we will have will also need two recycles, one from the last aerated reactor to the first anoxic reactor, and another one from the clarifer to the anoxic reactor

[3]:

# As always, firstly we need to set the components we want to work with,

# here we will just load the default components

cmps = qs.Components.load_default()

[4]:

# Take a look at what we have

cmps

CompiledComponents([S_H2, S_CH4, S_CH3OH, S_Ac, S_Prop, S_F, S_U_Inf, S_U_E, C_B_Subst, C_B_BAP, C_B_UAP, C_U_Inf, X_B_Subst, X_OHO_PHA, X_GAO_PHA, X_PAO_PHA, X_GAO_Gly, X_PAO_Gly, X_OHO, X_AOO, X_NOO, X_AMO, X_PAO, X_MEOLO, X_FO, X_ACO, X_HMO, X_PRO, X_U_Inf, X_U_OHO_E, X_U_PAO_E, X_Ig_ISS, X_MgCO3, X_CaCO3, X_MAP, X_HAP, X_HDP, X_FePO4, X_AlPO4, X_AlOH, X_FeOH, X_PAO_PP_Lo, X_PAO_PP_Hi, S_NH4, S_NO2, S_NO3, S_PO4, S_K, S_Ca, S_Mg, S_CO3, S_N2, S_O2, S_CAT, S_AN, H2O])

[5]:

# Just a refresher on how to set synonym

cmps.set_alias('H2O', 'Water')

cmps.H2O == cmps.Water

[5]:

True

[6]:

# Set the components

qs.set_thermo(cmps)

[7]:

# Make an influent waste stream

ww = qs.WasteStream.codbased_inf_model('ww', flow_tot=1000, units=('L/hr', 'mg/L'))

ww.show()

WasteStream: ww

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (g/hr): S_F 75

S_U_Inf 32.5

C_B_Subst 40

X_B_Subst 227

X_U_Inf 55.8

X_Ig_ISS 52.3

S_NH4 25

S_PO4 8

S_K 28

S_Ca 140

S_Mg 50

S_CO3 120

S_N2 18

S_CAT 3

S_AN 12

...

WasteStream-specific properties:

pH : 7.0

Alkalinity : 10.0 mg/L

COD : 430.0 mg/L

BOD : 249.4 mg/L

TC : 265.0 mg/L

TOC : 137.6 mg/L

TN : 40.0 mg/L

TP : 10.0 mg/L

TK : 28.0 mg/L

Component concentrations (mg/L):

S_F 75.0

S_U_Inf 32.5

C_B_Subst 40.0

X_B_Subst 226.7

X_U_Inf 55.8

X_Ig_ISS 52.3

S_NH4 25.0

S_PO4 8.0

S_K 28.0

S_Ca 140.0

S_Mg 50.0

S_CO3 120.0

S_N2 18.0

S_CAT 3.0

S_AN 12.0

...

[8]:

# Make the first two anoxic reactors

A1 = qs.sanunits.MixTank('A1', ins=(ww, 'recycle1', 'recycle2'),

tau=1, V_wf=0.8, init_with='WasteStream')

A2 = qs.sanunits.MixTank('A2', ins=A1-0, tau=1, V_wf=0.8, init_with='WasteStream')

Note that for A1, we saved two spots for recycles by just giving them the IDs of “recycle1” and “recycle2”, we will connect them to the corresponding units after we create them later.

Additionally, when creating A2, we indicated that the ins=A1-0, the expression with hyphen - is called “-pipe-notation”, briefly (U1, U2, and U3 are just units):

U1-0is equivalent toU1.outs[0]0-U1is equivalent toU1.ins[0]U1-0-1-U2is equivalent toU2.ins[1] = U1.outs[0]Note that

U1-0-1-U2is not equivalent toU2-1-0-U1, which meansU1.outs[0] = U2.ins[1](likea = b, which gives the value ofbtoa, is not the same asb = a, which gives the value ofatob)If

U1just has one effluent andU2just have one influent, we can useU1-U2

This is applicable for multiple influents/effluents as well, e.g.,

(U1-0, U3-0)-U2is equivalent toU2.ins[0] = U1.outs[0]andU2.ins[1] = U3.outs[0]

[9]:

# Then have three O2 streams, assuming we are just pumping air

# in case it's not already clear, I'm making up all the numbers

oxy1 = qs.WasteStream('oxy1', S_O2=ww.F_mass*0.01)

oxy1.imol['S_N2'] = oxy1.imol['S_O2']/0.21*0.79

oxy2 = oxy1.copy('oxy2')

oxy3 = oxy1.copy('oxy3')

[10]:

# Setting up the three aerated tanks

O1 = qs.sanunits.MixTank('O1', ins=(A2-0, oxy1), tau=1, V_wf=0.8, init_with='WasteStream')

O2 = qs.sanunits.MixTank('O2', ins=(O1-0, oxy2), tau=1, V_wf=0.8, init_with='WasteStream')

O3 = qs.sanunits.MixTank('O3', ins=(O2-0, oxy3), tau=1, V_wf=0.8, init_with='WasteStream')

[11]:

# Now note that we need to set up a splitter after the last aerated tank,

# to create the recycle stream

S1 = qs.sanunits.Splitter('S1', ins=O3-0, outs=('', 1-A1), # `''` means we use default ID

split=0.9, init_with='WasteStream')

[12]:

# Add in the clarifier, which is actually also a splitter

# (if we ignore the part that splitter does not have costs),

# since it's a clarifier, let's assume that 90% of the solubles

# (including dissolved gas and colloidal) will

# go to the liquid stream while 10% go to the sludge,

# and all solids go to the sludge

split_dct = {i.ID: 0.9 if i.particle_size != 'Particulate' else 0 for i in cmps }

Tip¶

After you become more familiar with Python, you’ll enjoy using one-liners since it’s much shorter (and can be faster). As in the case above when I set split_dct, it is equivalent to:

split_dct = {}

for i in cmps:

if i.particle_size == 'Particulate':

split_dct[i.ID] = 0

else:

split_dct[i.ID] = 1

[13]:

S2 = qs.sanunits.Splitter('S2', ins=S1-0, outs=('liquid_eff', 2-A1),

split=split_dct, init_with='WasteStream')

[14]:

# It's time to create the system!

# Since one system can only handle one recycle,

# we need to make two systems

import biosteam as bst

internal_sys = bst.System('internal_sys',

path=(A1, A2, O1, O2, O3, S1), # all units within this internal sys

recycle=S1-1 # the recycle stream

)

[15]:

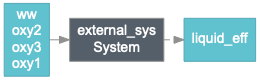

# When creating the second system,

# we can include the first one in the `path`

external_sys = bst.System('external_sys',

path=(internal_sys, S2),

recycle=S2-1

)

[16]:

# Tada~! Let's take a look at the system

external_sys.diagram()

Back to top

2. Retrieving useful information¶

Now that we have the system, we can retrieve information using the many attributes System has.

[17]:

# Give it a shorthand since I'm lazy...

sys = external_sys

[18]:

# Firstly, if you want to look at what units are within the system

sys.units

[18]:

[<MixTank: A1>,

<MixTank: A2>,

<MixTank: O1>,

<MixTank: O2>,

<MixTank: O3>,

<Splitter: S1>,

<Splitter: S2>]

[19]:

# Which is different from

sys.path

[19]:

(<System: internal_sys>, <Splitter: S2>)

[20]:

# Similar to units, you need to first simulate the system

# before you check out attributes that are not set up

# upon initialization (e.g., units, recycles)

sys.simulate()

sys

System: external_sys

Highest convergence error among components in recycle

stream S2-1 after 2 loops:

- flow rate 6.03e-01 kmol/hr (48%)

- temperature 0.00e+00 K (0%)

ins...

[0] ww

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (kmol/hr): S_F 0.075

S_U_Inf 0.0325

C_B_Subst 0.04

X_B_Subst 0.227

X_U_Inf 0.0558

X_Ig_ISS 0.0523

S_NH4 0.00147

...

[1] oxy1

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (kmol/hr): S_N2 1.17

S_O2 0.312

[2] oxy2

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (kmol/hr): S_N2 1.17

S_O2 0.312

[3] oxy3

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (kmol/hr): S_N2 1.17

S_O2 0.312

outs...

[0] liquid_eff

phase: 'l', T: 298.15 K, P: 101325 Pa

flow (kmol/hr): S_F 0.0734

S_U_Inf 0.0319

C_B_Subst 0.0392

S_NH4 0.00144

S_PO4 4.06e-05

S_K 0.000701

S_Ca 0.00342

...

In the above printout, you’ll are actually looking at the following attributes: - sys.diagram('minimal') - sys._error_info() - sys.feeds - sys.products

[21]:

# Ones related to costs

print(f'Purchase cost of the system equipment is {sys.purchase_cost:.0f} USD.')

print(f'Installed cost of the system equipment is {sys.installed_equipment_cost:.0f} USD.')

Purchase cost of the system equipment is 88771 USD.

Installed cost of the system equipment is 146473 USD.

[22]:

# If you set the operating hour of the system,

# you can also see costs related to operation

sys.operating_hours = 365*0.8

[23]:

# Electricity

print(f'This system uses {sys.get_electricity_consumption():.2f} kWh electricity per year.')

print(f'This system produces {sys.get_electricity_production():.2f} kWh electricity per year.')

This system uses 259.21 kWh electricity per year.

This system produces 0.00 kWh electricity per year.

[24]:

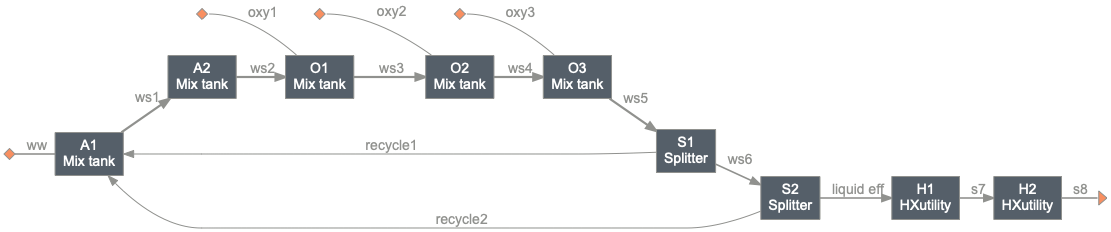

# And many others related to heating and cooling utilities,

# since there is no use of heating/cooling duties in our system,

# let's just add two new units to demonstrate it

H1 = qs.sanunits.HXutility('H1', ins=sys-0, T=50+273.15)

H2 = qs.sanunits.HXutility('H2', ins=H1-0, T=20+273.15)

sys2 = bst.System('sys2', path=(sys, H1, H2))

sys2.operating_hours = sys.operating_hours

sys2.simulate()

sys2.diagram()

print(f'Cooling duty of the second system is {sys2.get_cooling_duty():.2f} kJ per year.')

print(f'Heating duty of the second system is {sys2.get_heating_duty():.2f} kJ per year.')

Cooling duty of the second system is 37635939.66 kJ per year.

Heating duty of the second system is 33018236.42 kJ per year.

Back to top