Process Modeling 101¶

Prepared by:

Covered topics:

1. Introduction

2. System Setup

3. System Simulation

To run tutorials in your browser, go to this Binder page.

[1]:

import qsdsan as qs

print(f'This tutorial was made with qsdsan v{qs.__version__}.')

This tutorial was made with qsdsan v1.2.1.

[2]:

# Import packages

import numpy as np, pandas as pd

from qsdsan import sanunits as su, processes as pc, WasteStream, System

from qsdsan.utils import time_printer, load_data, get_SRT

import warnings

warnings.filterwarnings('ignore') # to ignore Pandas future warning & NumbaPerformanceWarning

1. Introduction¶

In this tutorial, we will explore how each QSDsan class is used in practical process simulation.

For this purpose, we will utilize an example system consisting of five-compartment activated sludge reactor followed by a flat-bottom circular clarifier. In addition, as a process model, Activated Sludge Model No. 2d (ASM2d) will be employed.

Back to top

2. System Setup¶

2.1. Component¶

Chemicals or biomass existing in a system can be expressed using the Component class of QSDsan.

[3]:

# Components

cmps = pc.create_asm2d_cmps() # create components of ASM2d

# you don't need to define each component one by one.

# compiled components for ASM2d are already available.

cmps.show() # 18 components of ASM2d + water (X_TSS was excluded due to redundancy.)

CompiledComponents([S_O2, S_N2, S_NH4, S_NO3, S_PO4, S_F, S_A, S_I, S_ALK, X_I, X_S, X_H, X_PAO, X_PP, X_PHA, X_AUT, X_MeOH, X_MeP, H2O])

S_O2: Dissolved oxygen, S_N2: Dinitrogen, S_NH4: Ammonium plus ammonia nitrogen, S_NO3: Nitrate plus nitrite nitrogen (NO3-N + NO2-N), S_PO4: Inorganic soluble phosphorus, primarily orthophosphates, S_F: Fermentable, readily biodegradable organic substrates, S_A: Fermentation products, considered to be acetate, S_I: Inert soluble organic material, S_ALK: Alkalinity of the wastewater, X_I: Inert particulate organic material, X_S: Slowly biodegradable substrates, X_H: Heterotrophic organisms, X_PAO: Phosphate-accumulating organisms, PAO, X_PP: Poly-phosphate, X_PHA: A cell internal storage product of phosphorus-accumulating organisms, PAO, X_AUT: Nitrifying organisms, X_MeOH: Metal-hydroxides, X_MeP: Metal-phosphate, MePO4

[4]:

cmps.S_A.show(chemical_info=True) # each component stores thermodynamic properties.

Component: S_A (phase_ref='l')

[Names] CAS: 64-19-7

InChI: C2H4O2/c1-2(3)4/h1H3...

InChI_key: QTBSBXVTEAMEQO-U...

common_name: acetic acid

iupac_name: ('ethanoic acid...

pubchemid: 176

smiles: CC(=O)O

formula: C2H4O2

[Groups] Dortmund: <1CH3, 1COOH>

UNIFAC: <1CH3, 1COOH>

PSRK: <1CH3, 1COOH>

NIST: <Empty>

[Data] MW: 60.052 g/mol

Tm: 289.85 K

Tb: 391.05 K

Tt: 289.69 K

Tc: 590.7 K

Pt: 1267.7 Pa

Pc: 5.78e+06 Pa

Vc: 0.000171 m^3/mol

Hf: -4.8358e+05 J/mol

S0: 159.8 J/K/mol

LHV: 7.87e+05 J/mol

HHV: 8.7502e+05 J/mol

Hfus: 11730 J/mol

Sfus: None

omega: 0.4218

dipole: 1.7 Debye

similarity_variable: 0.13322

iscyclic_aliphatic: 0

combustion: {'CO2': 2, 'O2'...

Component-specific properties:

[Others] measured_as: COD

description: Acetate

particle_size: Soluble

degradability: Readily

organic: True

i_C: 0.37535 g C/g COD

i_N: 0 g N/g COD

i_P: 0 g P/g COD

i_K: 0 g K/g COD

i_Mg: 0 g Mg/g COD

i_Ca: 0 g Ca/g COD

i_mass: 0.93835 g mass/g COD

i_charge: -0.015625 mol +/g COD

i_COD: 1 g COD/g COD

i_NOD: 0 g NOD/g COD

f_BOD5_COD: 0.717

f_uBOD_COD: 0.8628

f_Vmass_Totmass: 1

chem_MW: 60.052

2.2. WasteStream¶

Mass and energy flow within the system can be represented using the WastStream class of QSDsan.

[5]:

# Parameters (flowrates, temperature)

Q_inf = 18446 # influent flowrate [m3/d]

Q_was = 385 # sludge wastage flowrate [m3/d]

Q_ext = 18446 # external recycle flowrate [m3/d]

# internal recycle flowrate will be defined later using split ratio.

# effluent flowrate will be calculated as the amount remaining after recycling and wastage.

Temp = 273.15+20 # temperature [K]

[6]:

# Create influent, effluent, recycle stream

influent = WasteStream('influent', T=Temp) # create an empty wastestream with specified temperature

effluent = WasteStream('effluent', T=Temp)

int_recycle = WasteStream('internal_recycle', T=Temp)

ext_recycle = WasteStream('external_recycle', T=Temp)

wastage = WasteStream('wastage', T=Temp) # streams between the reactors will be

# automatically assigned when we define SanUnit.

[7]:

# Set the influent composition

default_inf_kwargs = { # default influent composition

'concentrations': { # you can set concentration of each component separately.

'S_I': 14,

'X_I': 26.5,

'S_F': 20.1,

'S_A': 94.3,

'X_S': 409.75,

'S_NH4': 31,

'S_N2': 0,

'S_NO3': 0.266,

'S_PO4': 2.8,

'X_PP': 0.05,

'X_PHA': 0.5,

'X_H': 0.15,

'X_AUT': 0,

'X_PAO': 0,

'S_ALK':7*12,

},

'units': ('m3/d', 'mg/L'), # ('input total flowrate', 'input concentrations')

}

influent.set_flow_by_concentration(Q_inf, **default_inf_kwargs) # set flowrate and composition of empty influent WasteStream

[8]:

influent # wastestream stores bulk properties of the stream, as well as concentration of each component.

WasteStream: influent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (g/hr): S_NH4 2.38e+04

S_NO3 204

S_PO4 2.15e+03

S_F 1.54e+04

S_A 7.25e+04

S_I 1.08e+04

S_ALK 6.46e+04

X_I 2.04e+04

X_S 3.15e+05

X_H 115

X_PP 38.4

X_PHA 384

H2O 7.67e+08

WasteStream-specific properties:

pH : 7.0

Alkalinity : 2.5 mg/L

COD : 565.3 mg/L

BOD : 320.1 mg/L

TC : 271.4 mg/L

TOC : 187.4 mg/L

TN : 48.9 mg/L

TP : 7.4 mg/L

TK : 0.1 mg/L

Component concentrations (mg/L):

S_NH4 31.0

S_NO3 0.3

S_PO4 2.8

S_F 20.1

S_A 94.3

S_I 14.0

S_ALK 84.0

X_I 26.5

X_S 409.8

X_H 0.2

X_PP 0.1

X_PHA 0.5

H2O 998426.3

[9]:

influent.get_VSS() # you can also retreive other information, such as VSS, TSS, TDS, etc.

[9]:

324.9843750592503

2.3. Process¶

Chemical or biological reactions occurring within the system can be included using the Process class of QSDsan.

2.3.1. Aeration¶

[10]:

# Parameters (volumes)

V_an = 1000 # anoxic zone tank volume [m3/d]

V_ae = 1333 # aerated zone tank volume [m3/d]

[11]:

# Aeration model

aer1 = pc.DiffusedAeration('aer1', DO_ID='S_O2', KLa=240, DOsat=8.0, V=V_ae) # aeration model for Tank 3 & Tank 4

aer2 = pc.DiffusedAeration('aer2', DO_ID='S_O2', KLa=84, DOsat=8.0, V=V_ae) # aeration model for Tank 5

DO_ID: The component ID of dissolved oxygen (DO). KLa: Oxygen mass transfer coefficient. DOsat: Surface DO saturation concentration. V: Reactor volume

[12]:

aer1

Process: aer1

[stoichiometry] S_O2: 1

[reference] S_O2

[rate equation] KLa*(DOsat - S_O2)

[parameters] KLa: 240

DOsat: 8

[dynamic parameters]

2.3.2. ASM2d¶

[13]:

# ASM2d

asm2d = pc.ASM2d() # create ASM2d processes

asm2d.show() # 21 processes in ASM2d

ASM2d([aero_hydrolysis, anox_hydrolysis, anae_hydrolysis, hetero_growth_S_F, hetero_growth_S_A, denitri_S_F, denitri_S_A, ferment, hetero_lysis, PAO_storage_PHA, aero_storage_PP, PAO_aero_growth_PHA, PAO_lysis, PP_lysis, PHA_lysis, auto_aero_growth, auto_lysis, precipitation, redissolution, anox_storage_PP, PAO_anox_growth])

[14]:

asm2d.aero_hydrolysis # Each process includes stoichiometry, rate equation, and parameters.

Process: aero_hydrolysis

[stoichiometry] S_NH4: 0.02*f_SI + 0.01

S_PO4: 0.01*f_SI

S_F: 1.0 - 1.0*f_SI

S_I: 1.0*f_SI

S_ALK: 0.0113*f_SI + 0.00858

X_S: -1.00

[reference] X_S

[rate equation] K_h*S_O2*X_S/((K_O2 + S_O2)*...

[parameters] f_SI: 0

Y_H: 0.625

f_XI_H: 0.1

Y_PAO: 0.625

Y_PO4: 0.4

Y_PHA: 0.2

f_XI_PAO: 0.1

Y_A: 0.24

f_XI_AUT: 0.1

K_h: 3

eta_NO3: 0.6

eta_fe: 0.4

K_O2: 0.2

K_NO3: 0.5

K_X: 0.1

mu_H: 6

q_fe: 3

eta_NO3_H: 0.8

b_H: 0.4

K_O2_H: 0.2

K_F: 4

K_fe: 4

K_A_H: 4

K_NO3_H: 0.5

K_NH4_H: 0.05

K_P_H: 0.01

K_ALK_H: 1.2

q_PHA: 3

q_PP: 1.5

mu_PAO: 1

eta_NO3_PAO: 0.6

b_PAO: 0.2

b_PP: 0.2

b_PHA: 0.2

K_O2_PAO: 0.2

K_NO3_PAO: 0.5

K_A_PAO: 4

K_NH4_PAO: 0.05

K_PS: 0.2

K_P_PAO: K_P_PAO

K_ALK_PAO: 1.2

K_PP: 0.01

K_MAX: 0.34

K_IPP: 0.02

K_PHA: 0.01

mu_AUT: 1

b_AUT: 0.15

K_O2_AUT: 0.5

K_NH4_AUT: 1

K_ALK_AUT: 6

K_P_AUT: 0.01

k_PRE: 1

k_RED: 0.6

K_ALK_PRE: 6

K_P_PAO: 0.01

[dynamic parameters]

[15]:

# Petersen stoichiometric matrix of ASM2d

pd.set_option('display.max_columns', None) # to display all columns

asm2d.stoichiometry

[15]:

| S_O2 | S_N2 | S_NH4 | S_NO3 | S_PO4 | S_F | S_A | S_I | S_ALK | X_I | X_S | X_H | X_PAO | X_PP | X_PHA | X_AUT | X_MeOH | X_MeP | H2O | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| aero_hydrolysis | 0 | 0 | 0.01 | 0 | 0 | 1 | 0 | 0 | 0.00858 | 0 | -1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| anox_hydrolysis | 0 | 0 | 0.01 | 0 | 0 | 1 | 0 | 0 | 0.00858 | 0 | -1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| anae_hydrolysis | 0 | 0 | 0.01 | 0 | 0 | 1 | 0 | 0 | 0.00858 | 0 | -1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| hetero_growth_S_F | -0.6 | 0 | -0.022 | 0 | -0.004 | -1.6 | 0 | 0 | -0.0165 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| hetero_growth_S_A | -0.6 | 0 | -0.07 | 0 | -0.02 | 0 | -1.6 | 0 | 0.252 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| denitri_S_F | 0 | 0.21 | -0.022 | -0.21 | -0.004 | -1.6 | 0 | 0 | 0.164 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| denitri_S_A | 0 | 0.21 | -0.07 | -0.21 | -0.02 | 0 | -1.6 | 0 | 0.432 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| ferment | 0 | 0 | 0.03 | 0 | 0.01 | -1 | 1 | 0 | -0.168 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| hetero_lysis | 0 | 0 | 0.032 | 0 | 0.01 | 0 | 0 | 0 | 0.0216 | 0.1 | 0.9 | -1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| PAO_storage_PHA | 0 | 0 | 0 | 0 | 0.4 | 0 | -1 | 0 | 0.11 | 0 | 0 | 0 | 0 | -0.4 | 1 | 0 | 0 | 0 | 0 |

| aero_storage_PP | -0.2 | 0 | 0 | 0 | -1 | 0 | 0 | 0 | 0.194 | 0 | 0 | 0 | 0 | 1 | -0.2 | 0 | 0 | 0 | 0 |

| PAO_aero_growth_PHA | -0.6 | 0 | -0.07 | 0 | -0.02 | 0 | 0 | 0 | -0.0484 | 0 | 0 | 0 | 1 | 0 | -1.6 | 0 | 0 | 0 | 0 |

| PAO_lysis | 0 | 0 | 0.032 | 0 | 0.01 | 0 | 0 | 0 | 0.0216 | 0.1 | 0.9 | 0 | -1 | 0 | 0 | 0 | 0 | 0 | 0 |

| PP_lysis | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | -0.194 | 0 | 0 | 0 | 0 | -1 | 0 | 0 | 0 | 0 | 0 |

| PHA_lysis | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | -0.188 | 0 | 0 | 0 | 0 | 0 | -1 | 0 | 0 | 0 | 0 |

| auto_aero_growth | -18 | 0 | -4.24 | 4.17 | -0.02 | 0 | 0 | 0 | -7.2 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| auto_lysis | 0 | 0 | 0.032 | 0 | 0.01 | 0 | 0 | 0 | 0.0216 | 0.1 | 0.9 | 0 | 0 | 0 | 0 | -1 | 0 | 0 | 0 |

| precipitation | 0 | 0 | 0 | 0 | -1 | 0 | 0 | 0 | 0.582 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | -3.45 | 4.87 | 0 |

| redissolution | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | -0.582 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.45 | -4.87 | 0 |

| anox_storage_PP | 0 | 0.07 | 0 | -0.07 | -1 | 0 | 0 | 0 | 0.254 | 0 | 0 | 0 | 0 | 1 | -0.2 | 0 | 0 | 0 | 0 |

| PAO_anox_growth | 0 | 0.208 | -0.0683 | -0.21 | -0.02 | 0 | 0 | 0 | 0.133 | 0 | 0 | 0 | 1 | 0 | -1.6 | 0 | 0 | 0 | 0 |

[16]:

# Rate equations of ASM2d

asm2d.rate_equations

[16]:

| rate_equation | |

|---|---|

| aero_hydrolysis | 3.0*S_O2*X_S/((0.1 + X_S/X_H)*(... |

| anox_hydrolysis | 0.36*S_NO3*X_S/((0.1 + X_S/X_H)... |

| anae_hydrolysis | 0.12*X_S/((0.1 + X_S/X_H)*(S_NO... |

| hetero_growth_S_F | 6.0*S_ALK*S_F**2*S_NH4*S_O2*S_P... |

| hetero_growth_S_A | 6.0*S_A**2*S_ALK*S_NH4*S_O2*S_P... |

| denitri_S_F | 0.96*S_ALK*S_F**2*S_NH4*S_NO3*S... |

| denitri_S_A | 0.96*S_A**2*S_ALK*S_NH4*S_NO3*S... |

| ferment | 0.3*S_ALK*S_F*X_H/((S_ALK + 1.2... |

| hetero_lysis | 0.4*X_H |

| PAO_storage_PHA | 3.0*S_A*S_ALK*X_PP/((0.01 + X_P... |

| aero_storage_PP | 1.5*S_ALK*S_O2*S_PO4*X_PHA*(0.3... |

| PAO_aero_growth_PHA | 1.0*S_ALK*S_NH4*S_O2*S_PO4*X_PH... |

| PAO_lysis | 0.2*S_ALK*X_PAO/(S_ALK + 1.2) |

| PP_lysis | 0.2*S_ALK*X_PP/(S_ALK + 1.2) |

| PHA_lysis | 0.2*S_ALK*X_PHA/(S_ALK + 1.2) |

| auto_aero_growth | 1.0*S_ALK*S_NH4*S_O2*S_PO4*X_AU... |

| auto_lysis | 0.15*X_AUT |

| precipitation | 1.0*S_PO4*X_MeOH |

| redissolution | 0.6*S_ALK*X_MeP/(S_ALK + 6.0) |

| anox_storage_PP | 0.18*S_ALK*S_NO3*S_PO4*X_PHA*(0... |

| PAO_anox_growth | 0.12*S_ALK*S_NH4*S_NO3*S_PO4*X_... |

2.4. SanUnit¶

Reactors constituting the system can be represented using the SanUnit class of QSDsan.

[17]:

# Anoxic reactors (Tank 1 & Tank 2)

A1 = su.CSTR('A1', ins=[influent, int_recycle, ext_recycle], V_max=V_an, # As CSTR, 3 input streams, tank volume as V_an

aeration=None, suspended_growth_model=asm2d) # No aeration, biokinetic model as asm2d

A2 = su.CSTR('A2', ins=A1-0, V_max=V_an, # ins=A1-0: set influent of A2 as effluent of A1 reactor (to connect A1 with A2)

aeration=None, suspended_growth_model=asm2d)

ins: Influents to the reactor. outs: Treated effluent from the reactor. V_max: Designed volume, in [m^3]. The default is 1000. aeration: Aeration setting. Either specify a targeted dissolved oxygen concentration in [mg O2/L] or provide a :class:Process object to represent aeration, or None for no aeration. The default is 2.0. suspended_growth_model: The suspended growth biokinetic model. The default is None.

[18]:

A1 # Before simulation, outs are empty.

CSTR: A1

ins...

[0] influent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (g/hr): S_NH4 2.38e+04

S_NO3 204

S_PO4 2.15e+03

S_F 1.54e+04

S_A 7.25e+04

S_I 1.08e+04

S_ALK 6.46e+04

X_I 2.04e+04

X_S 3.15e+05

X_H 115

X_PP 38.4

X_PHA 384

H2O 7.67e+08

WasteStream-specific properties:

pH : 7.0

COD : 565.3 mg/L

BOD : 320.1 mg/L

TC : 271.4 mg/L

TOC : 187.4 mg/L

TN : 48.9 mg/L

TP : 7.4 mg/L

TK : 0.1 mg/L

[1] internal_recycle

phase: 'l', T: 293.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

[2] external_recycle

phase: 'l', T: 293.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

outs...

[0] ws1 to CSTR-A2

phase: 'l', T: 298.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

[19]:

# Aerated reactors (Tank 3, Tank 4, Tank 5)

O1 = su.CSTR('O1', ins=A2-0, V_max=V_ae, aeration=aer1, # tank volume as V_ae with aeration model1

DO_ID='S_O2', suspended_growth_model=asm2d)

O2 = su.CSTR('O2', ins=O1-0, V_max=V_ae, aeration=aer1,

DO_ID='S_O2', suspended_growth_model=asm2d)

O3 = su.CSTR('O3', ins=O2-0, outs=[int_recycle, 'treated'], split=[0.6, 0.4], # 60% of efflunet to internal recycle, 40% to clarifier

V_max=V_ae, aeration=aer2,

DO_ID='S_O2', suspended_growth_model=asm2d)

[20]:

O3

CSTR: O3

ins...

[0] ws7 from CSTR-O2

phase: 'l', T: 298.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

outs...

[0] internal_recycle to CSTR-A1

phase: 'l', T: 293.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

[1] treated

phase: 'l', T: 298.15 K, P: 101325 Pa

flow: 0

WasteStream-specific properties: None for empty waste streams

[21]:

# Clarifier

C1 = su.FlatBottomCircularClarifier('C1', ins=O3-1, outs=[effluent, ext_recycle, wastage], # O3-1: second effluent of O3, three outs

underflow=Q_ext, wastage=Q_was, surface_area=1500,

height=4, N_layer=10, feed_layer=5, # modeled as a 10 layer non-reactive unit

X_threshold=3000, v_max=474, v_max_practical=250,

rh=5.76e-4, rp=2.86e-3, fns=2.28e-3)

underflow: Designed recycling sludge flowrate (RAS), in [m^3/d]. The default is 2000. wastage: Designed wasted sludge flowrate (WAS), in [m^3/d]. The default is 385. surface_area: Surface area of the clarifier, in [m^2]. The default is 1500. height: Height of the clarifier, in [m]. The default is 4. N_layer: The number of layers to model settling. The default is 10. feed_layer: The feed layer counting from top to bottom. The default is 4. X_threshold: Threshold suspended solid concentration, in [g/m^3]. The default is 3000. v_max: Maximum theoretical (i.e. Vesilind) settling velocity, in [m/d]. The default is 474. v_max_practical: Maximum practical settling velocity, in [m/d]. The default is 250. rh: Hindered zone settling parameter in the double-exponential settling velocity function, in [m^3/g]. The default is 5.76e-4. rp: Flocculant zone settling parameter in the double-exponential settling velocity function, in [m^3/g]. The default is 2.86e-3. fns: Non-settleable fraction of the suspended solids, dimensionless. Must be within [0, 1]. The default is 2.28e-3.

2.5. System¶

System objects are used to organize unit operations in a certain order and facilitate mass and energy convergence, techno-economic analysis (TEA), and life cycle assessment (LCA).

2.5.1. Create system¶

[22]:

# Create system

sys = System('example_system', path=(A1, A2, O1, O2, O3, C1), recycle=(int_recycle, ext_recycle)) # path: the order of reactor

[23]:

# System diagram

sys.diagram()

[24]:

sys # before running the simulation, 'outs' have nothing

System: example_system

ins...

[0] influent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (kmol/hr): S_NH4 1.4

S_NO3 0.0033

S_PO4 0.0112

S_F 15.4

S_A 1.21

S_I 10.8

S_ALK 1.06

... 4.29e+04

outs...

[0] effluent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow: 0

[1] wastage

phase: 'l', T: 293.15 K, P: 101325 Pa

flow: 0

2.5.2. Set initial conditions of reactors¶

[25]:

# Import initial condition excel file

df = load_data('assets/tutorial_13/initial_conditions_asm2d.xlsx', sheet='default')

[26]:

df # Unlike other reactors, C1 has 3 rows for each of soluble, solids, and tss.

[26]:

| S_O2 | S_NH4 | S_NO3 | S_PO4 | S_F | S_A | S_I | S_ALK | X_I | X_S | X_H | X_PAO | X_PP | X_PHA | X_AUT | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.00213 | 7.23 | 10.2 | 4.45 | 0.211 | 0.0265 | 15.9 | 67 | 2.28e+03 | 84.4 | 3.78e+03 | 322 | 37.2 | 0.0517 | 218 |

| A2 | 0.001 | 22.4 | 2.4 | 4.24 | 6.68 | 53.8 | 14.5 | 79 | 0 | 84.1 | 207 | 18.2 | 4.25 | 3.59 | 11.9 |

| O2 | 2 | 16.5 | 4.31 | 5.48 | 1.9 | 2.73 | 13.7 | 82.6 | 611 | 77.3 | 1.04e+03 | 86.4 | 6.45 | 11 | 58 |

| O3 | 2 | 10.9 | 9.31 | 2.62 | 0.649 | 0.163 | 14.1 | 74.2 | 662 | 59.3 | 1.14e+03 | 95.7 | 9.99 | 7.24 | 64 |

| O1 | 2 | 0.111 | 26.1 | 2.32 | 0.276 | 0.00407 | 18.2 | 46.1 | 2.24e+03 | 61.1 | 3.79e+03 | 322 | 38.4 | 0.00852 | 218 |

| C1_s | 2 | 0.114 | 20.9 | 0.356 | 0.307 | 0.00537 | 20.1 | 49.6 | NaN | NaN | NaN | NaN | NaN | NaN | NaN |

| C1_x | NaN | NaN | NaN | NaN | NaN | NaN | NaN | NaN | 2.24e+03 | 61.1 | 3.79e+03 | 322 | 38.4 | 0.00852 | 218 |

| C1_tss | 17.8 | 27.9 | 44.9 | 90.5 | 305 | 304 | 306 | 304 | 304 | 5.83e+03 | NaN | NaN | NaN | NaN | NaN |

[27]:

# Create a function to set initial conditions of the reactors

def batch_init(sys, df):

dct = df.to_dict('index') # convert the DataFrame to a dictionary.

u = sys.flowsheet.unit # unit registry (A1, A2, O1, O2, O3, C1)

for k in [u.A1, u.A2, u.O1, u.O2, u.O3]: # for A1, A2, O1, O2, O3 reactor,

k.set_init_conc(**dct[k._ID]) # A1.set_init_conc(**dct[k_ID])

c1s = {k:v for k,v in dct['C1_s'].items() if v>0} # for clarifier, need to use different methods

c1x = {k:v for k,v in dct['C1_x'].items() if v>0}

tss = [v for v in dct['C1_tss'].values() if v>0]

u.C1.set_init_solubles(**c1s) # set solubles

u.C1.set_init_sludge_solids(**c1x) # set sludge solids

u.C1.set_init_TSS(tss) # set TSS

[28]:

batch_init(sys, df)

Back to top

3. System Simulation¶

3.1. Run simulation¶

[29]:

# Simulation settings

sys.set_dynamic_tracker(influent, effluent, A1, A2, O1, O2, O3, C1, wastage) # what you want to track changes in concentration

sys.set_tolerance(rmol=1e-6)

biomass_IDs = ('X_H', 'X_PAO', 'X_AUT')

[30]:

# Simulation settings

t = 50 # total time for simulation

t_step = 1 # times at which to store the computed solution

method = 'BDF' # integration method to use

# method = 'RK45'

# method = 'RK23'

# method = 'DOP853'

# method = 'Radau'

# method = 'LSODA'

# https://docs.scipy.org/doc/scipy/reference/generated/scipy.integrate.solve_ivp.html

[31]:

# Run simulation, this could take several minuates

sys.simulate(state_reset_hook='reset_cache',

t_span=(0,t),

t_eval=np.arange(0, t+t_step, t_step),

method=method,

# export_state_to=f'sol_{t}d_{method}.xlsx', # uncomment to export simulation result as excel file

)

[32]:

srt = get_SRT(sys, biomass_IDs)

print(f'Estimated SRT assuming at steady state is {round(srt, 2)} days')

Estimated SRT assuming at steady state is 10.02 days

[33]:

sys # now you have 'outs' info.

System: example_system

Highest convergence error among components in recycle

streams {C1-1, O3-0} after 5 loops:

- flow rate 1.17e-06 kmol/hr (9.1e-10%)

- temperature 2.63e-08 K (9e-09%)

ins...

[0] influent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (kmol/hr): S_NH4 1.4

S_NO3 0.0033

S_PO4 0.0112

S_F 15.4

S_A 1.21

S_I 10.8

S_ALK 1.06

... 4.29e+04

outs...

[0] effluent

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (kmol/hr): S_O2 0.000506

S_N2 0.00716

S_NH4 1.64

S_NO3 2.21e-09

S_PO4 0.015

S_F 0.973

S_A 0.111

... 4.17e+04

[1] wastage

phase: 'l', T: 293.15 K, P: 101325 Pa

flow (kmol/hr): S_O2 1.08e-05

S_N2 0.000153

S_NH4 0.0349

S_NO3 4.72e-11

S_PO4 0.000321

S_F 0.0207

S_A 0.00237

... 1.04e+03

3.2. Check simulation results¶

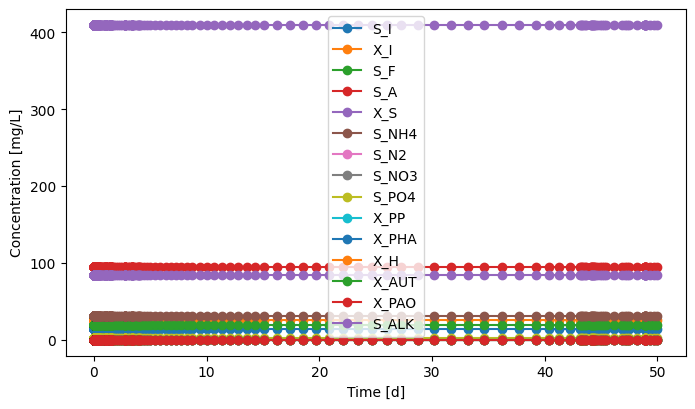

[34]:

# Influent

influent.scope.plot_time_series(('S_I','X_I','S_F','S_A','X_S','S_NH4','S_N2','S_NO3','S_PO4','X_PP','X_PHA',

'X_H','X_AUT','X_PAO','S_ALK')) # you can plot how each state variable changes over time

#default_inf_kwargs = {

# 'concentrations': {

# 'S_I': 14,

# 'X_I': 26.5,

# 'S_F': 20.1,

# 'S_A': 94.3,

# 'X_S': 409.75,

# 'S_NH4': 31,

# 'S_N2': 0,

# 'S_NO3': 0.266,

# 'S_PO4': 2.8,

# 'X_PP': 0.05,

# 'X_PHA': 0.5,

# 'X_H': 0.15,

# 'X_AUT': 0,

# 'X_PAO': 0,

# 'S_ALK':7*12,

# },

# 'units': ('m3/d', 'mg/L'),

# } # constant influent setting

[34]:

(<Figure size 800x450 with 1 Axes>,

<AxesSubplot:xlabel='Time [d]', ylabel='Concentration [mg/L]'>)

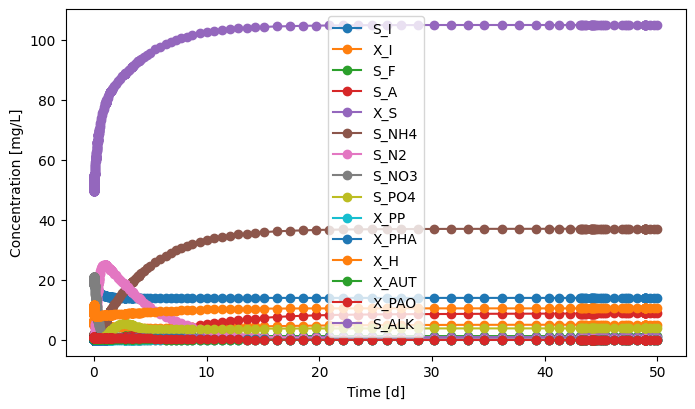

[35]:

# Effluent

effluent.scope.plot_time_series((('S_I','X_I','S_F','S_A','X_S','S_NH4','S_N2','S_NO3','S_PO4','X_PP','X_PHA',

'X_H','X_AUT','X_PAO','S_ALK'))) # you can plot how each state variable changes over time

[35]:

(<Figure size 800x450 with 1 Axes>,

<AxesSubplot:xlabel='Time [d]', ylabel='Concentration [mg/L]'>)

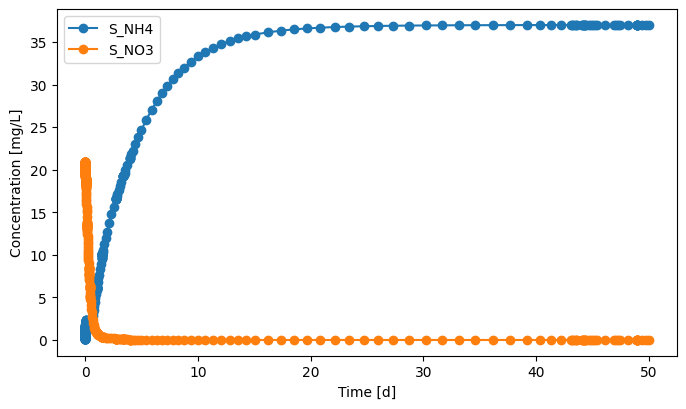

[36]:

effluent.scope.plot_time_series(('S_NH4', 'S_NO3')) # you can plot how each state variable changes over time

[36]:

(<Figure size 800x450 with 1 Axes>,

<AxesSubplot:xlabel='Time [d]', ylabel='Concentration [mg/L]'>)

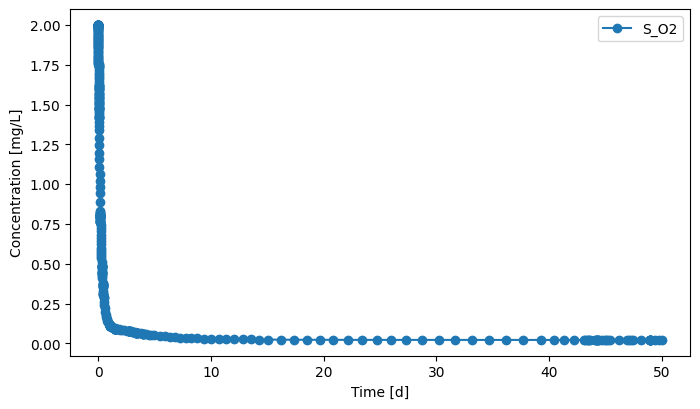

[37]:

effluent.scope.plot_time_series(('S_O2')) # you can plot how each state variable changes over time

[37]:

(<Figure size 800x450 with 1 Axes>,

<AxesSubplot:xlabel='Time [d]', ylabel='Concentration [mg/L]'>)

Back to top